12.4 / Presses & Equipment

1957 / No. 4 Proof Press

Bed: 15″ × 35″

(From 1950 Vandercook and 1953 WNU catalogues:)

Maximum sheet: 14¾” × 20″

Maximum form: 14″ × 18″

Floor space: 2’2″ × 6’6″

Weight: 1100 lb

I Bought this Press in 1996 from George at Mouldtype in Leyland, Preston. I had received what was known as ‘A setting-up Grant’ from the Crafts Council — where they offered 50% of the cost of equipment. It has been at the centre of my workshop for nearly thirty years.

At the time I had a space in Cable Street Studios in the docklands that I shared with Laurence Houghton. ‘Howie’ & I drove to Preston & back in a day in cheap old Luton hire van that wouldn’t go above 50MPH . . .

. . .

For reproduction and test proofs. Power ink distribution, type high bed, travelling sheet delivery tray. Optional split vibrator and riders.

(From 1957 Vandercook catalog:)

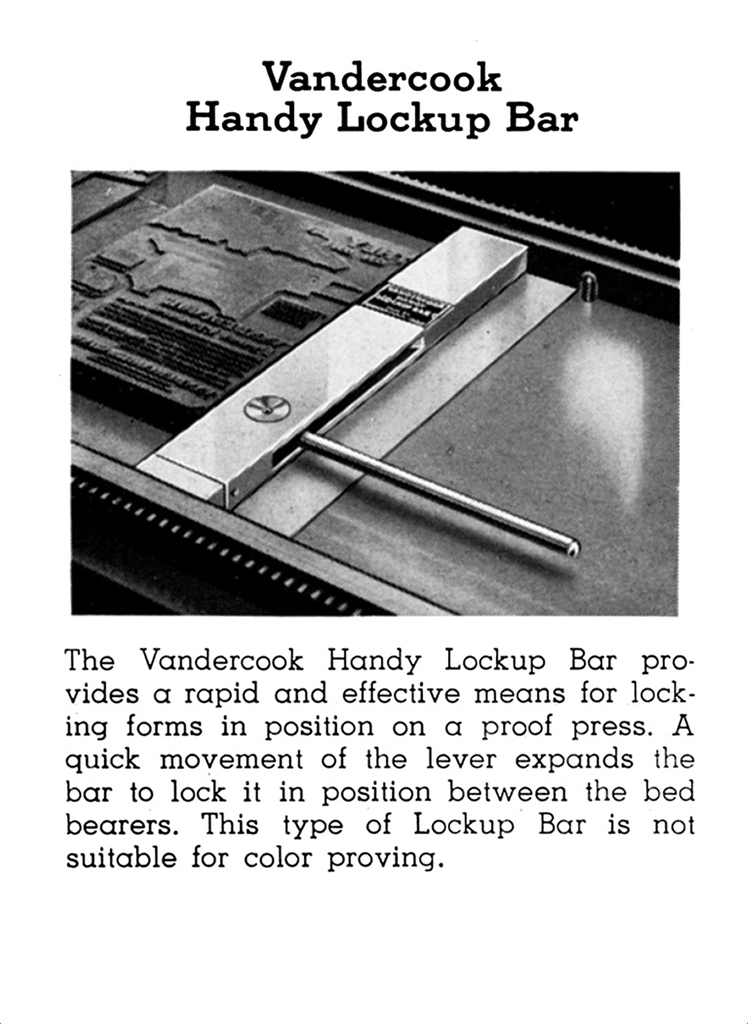

“Over 5000 in use today … Now also suitable for producing fine transparent proofs by equipping it with the transparency feeding equipment. ” Vandercook introduced the Handy Lockup Bar.